Custom embroidered patches and direct embroidery are two popular ways to add a custom design to fabric or garments. However, embroidered patches offer several advantages over direct embroidery.

What is Embroidered Patches?

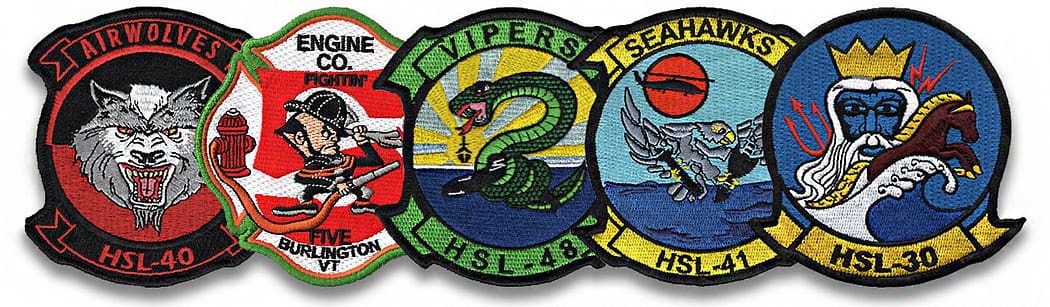

Embroidered patches are fabric pieces with a design or logo embroidered onto them using thread. They are a popular way to add customization and personalization to clothing, accessories, and other items. Embroidered patches are made using various materials, including cotton, polyester, and nylon, and can be made in different sizes, shapes, and colors.

Making embroidered patches typically involves using computerized embroidery machines to stitch the design onto the fabric. The devices use a needle and thread to create the design; the final product is a patch with a textured and raised appearance.

Embroidered patches are versatile and can be applied to various items, including hats, jackets, bags, and uniforms. They can be easily attached to clothing using an iron or sewing. Embroidered patches are famous for individuals, organizations, and businesses looking to add a custom touch to their clothing or accessories.

What Is Direct Embroidery?

Direct embroidery is a technique where the patch design is stitched directly onto the fabric or garment. This process involves using specialized equipment to embroider the design onto the material, making it a permanent part of the item. Once the patch has been applied using direct embroidery, it cannot be removed or repositioned.

Unlike embroidered patches, which can be easily removed and re-used on different items, direct embroidery permanently embeds the patch onto the fabric or garment, making it impossible to extract. Therefore, if you want to use the same patch design on a different item, you must order a new patch.

It’s essential to think about your needs and preferences before choosing between direct embroidery and embroidered patches. Direct embroidery may be the right choice if you’re looking for a permanent and durable way to customize your fabric or garment. However, embroidered patches are a better choice if you prefer a flexible and versatile option that can be easily removed and applied to different items.

Why Embroidered Patches are the Ideal Option?

Firstly, embroidered patches are more accessible to apply than direct embroidery. Direct embroidery requires the design to be stitched directly onto the fabric or garment, which can be difficult and time-consuming, especially for larger structures or intricate details. In contrast, pre-made embroidered patches can be easily applied to the garment with an iron or a few stitches.

Secondly, embroidered patches are more versatile. Direct embroidery can only be done on certain fabrics, while embroidered patches can be applied to almost any material or garment, including leather, nylon, and polyester. This versatility makes embroidered patches a better choice for uniforms, bags, hats, and other accessories that require a durable and customized finish.

Thirdly, embroidered patches are more cost-effective. Direct embroidery requires specialized equipment and skilled labor, which can be expensive. However, the advantage of patches over direct embroidery is that it is a more cost-effective option in the long run. Direct embroidery onto a garment costs between $3 to $5 A left chest patch costs between $0.5 to $1.5. Add the cost of sewing the patch onto a garment for around $0.5, at $1 to $2, which is still 200% cheaper than direct embroidery. Let’s say that your company has 20 employees, and each employee requires five garments with your company logo sewn onto it. That is 100 garments. An average price difference between an embroidered patch and direct embroidery is $2, which is $200 saved. Furthermore, in many industries, such as auto mechanics, gardening, and restaurants, uniforms must be changed at least twice yearly because the uniforms get dirty. The benefit of an embroidered patch is that you can cut the garment off and re-sew it onto a new one. So instead of paying an average of $3 to have the embroidery done again on a new shirt, you need to pay $0.5 to have the patch re-sewn onto a new garment. This is a savings of $2.5 or another $250. Suppose a company operates a staff of 20 people, each receiving five uniforms, with an average turnover of 2 times yearly on a uniform. In that case, the total savings are $500 per year—small but significant savings for a small business.

Lastly, embroidered patches offer a higher level of customization than direct embroidery. With embroidered patches, you can choose your design’s size, shape, and colors. You can also add details such as text, borders, and special effects, which may not be possible with direct embroidery.

Overall, embroidered patches are a better choice than direct embroidery due to their ease of application, versatility, cost-effectiveness, and customization options.

Where Can I Get Embroidered Patches Made?

If you are looking for a company to make your custom embroidered patches, consider Ruiji Clothing Label. We are a company that specializes in producing high-quality embroidered patches for various industries and purposes. We can create custom patches based on your design and specifications with their expertise and state-of-the-art equipment.

In addition to their quality artistry, Ruiji Clothing Label also offers their customers competitive pricing and fast turnaround times. We have a user-friendly website where you can easily upload your design and get a quick quote for your order. We also provide excellent customer service to ensure your experience is smooth and pleasant.

Whether you need embroidered patches for your business, organization, or personal use, Ruiji Clothing Label can provide you with the best options and solutions. Please contact them today to get started on your custom embroidered patches.